Why Development Boards Fall Short for Market Launch

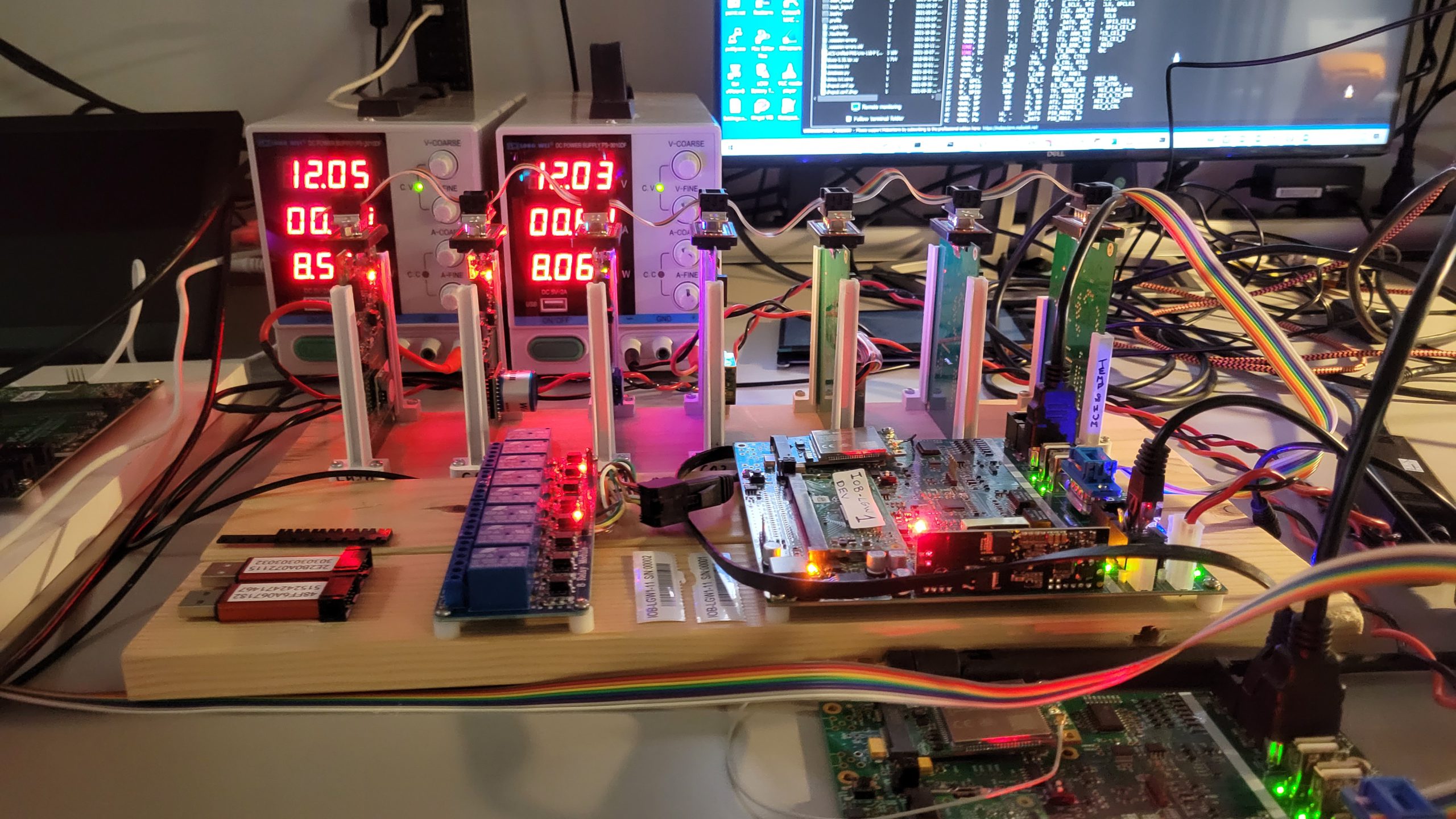

In the process of developing an electronic product, one of the most crucial steps is moving from a prototype that uses a development board to a market-ready product with a custom-designed circuit board. This transition is key to the long-term success of the product in the market. At GBX Technology, our expertise is in guiding companies through this vital transition. Our focus is on ensuring the final product is not just functionally efficient but also cost-effective and tailored to the specific demands of the market.

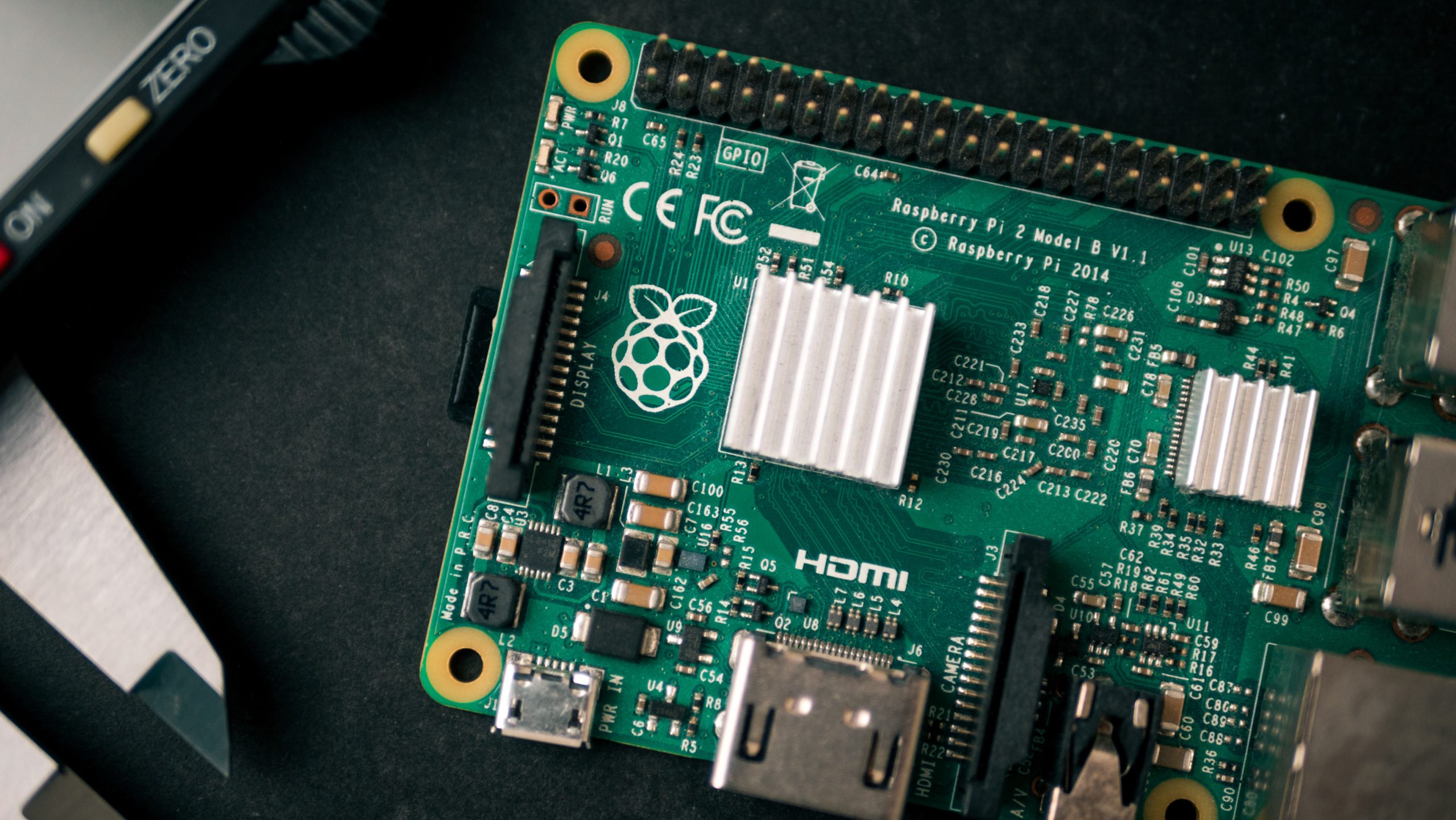

Development boards are excellent for initial prototyping, but they often lack the specialization and optimization needed for a commercially viable product. By switching to a custom-designed circuit board, we help you address this gap. This change brings several benefits: A reduction in the size and cost of the product, improved energy efficiency, and enhanced performance tailored to your specific use case.

Development boards are excellent for initial prototyping, but they often lack the specialization and optimization needed for a commercially viable product. By switching to a custom-designed circuit board, we help you address this gap. This change brings several benefits: A reduction in the size and cost of the product, improved energy efficiency, and enhanced performance tailored to your specific use case.

This not only saves money and time in the long run but also reduces the risks associated with bringing a new product to market. Let’s take a look at the potential risks and concepts to consider before your launching:

- Cost and Efficiency: Development boards, though excellent for prototyping, are costlier due to unnecessary extra components. They lack the cost-efficiency vital for a competitive market presence. At GBX, we focus on designing cost-effective, bespoke PCBs that align with your budget and product requirements.

- Design Constraints: The one-size-fits-all nature of development boards means compromising on size and design. We understand that product design is key to consumer appeal, and thus, we tailor PCB designs to fit your specific product dimensions and aesthetic requirements.

- Optimized Power Usage: Battery life is a critical factor in consumer electronics. Development boards are not optimized for power efficiency, leading to quicker battery drain. Our team at GBX ensures your product is energy-efficient, enhancing user experience and product longevity.

- Reliability and Endurance: Designed for experimentation, development boards may lack the durability required for long-term use. GBX Technology addresses this by developing robust PCBs that withstand rigorous use, ensuring product reliability and customer satisfaction.

- Customization for Specific Needs: Every product has unique needs, and development boards often fall short in customization. Our expertise lies in creating custom solutions that precisely meet your product’s functional requirements and market expectations.

- Scalability for Mass Production: Transitioning to mass production is a key step in product launch. Development boards are not suitable for this scale, whereas custom PCBs designed by GBX can be efficiently and cost-effectively mass-produced.

- Protecting Intellectual Property: Differentiating your product and protecting its intellectual property is vital. With custom PCBs, GBX helps safeguard your innovations, ensuring a unique and protected market entry.

Choosing a Trusted Technology Partner

Our role at GBX Technology is to make this transition seamless and informed. We understand the nuances of electronic product design and the importance of aligning with market trends and consumer expectations. Our goal is to deliver a product that not only meets but exceeds your business objectives and positions you as a leader in your market segment.

With GBX Technology, you’re partnering with a team that has the technical expertise and market knowledge to ensure your product’s success from the outset. We invite you to contact us to discuss your product, and let us assist you in making your market launch not just successful but exemplary.